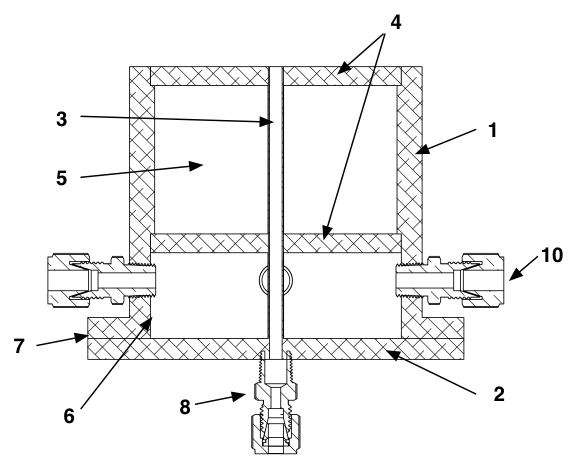

CAD drawings of the burner in different formats are available here.

Parts list - included with burner*the number in parenthesis refer to the schematics at the bottom of the parts list.

(2) Bottom Plate

(3) Fuel Tube

(4) Honeycomb:

(6) Screen: supports bottom honeycomb that confines glass beads.

(7) O-Ring: seals Coflow Housing to Bottom Plate.

(8) Fuel Tube Support Fitting:

Parts list - non included with burner

(9) Fuel Tube Connection Fitting

(10) Air Connection Fitting (x4)

(11) Nuts and Bolts (x4):

Assembly instruction:

Assembly

will take place in three sections: coflow housing, bottom

plate, and final assembly. Note: the following pictures show

a plastic 3D printed model of the burner. As specified

above, the actual burner body will be aluminum.

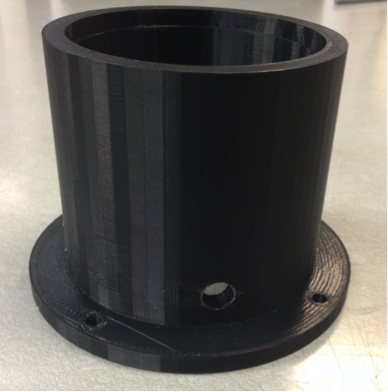

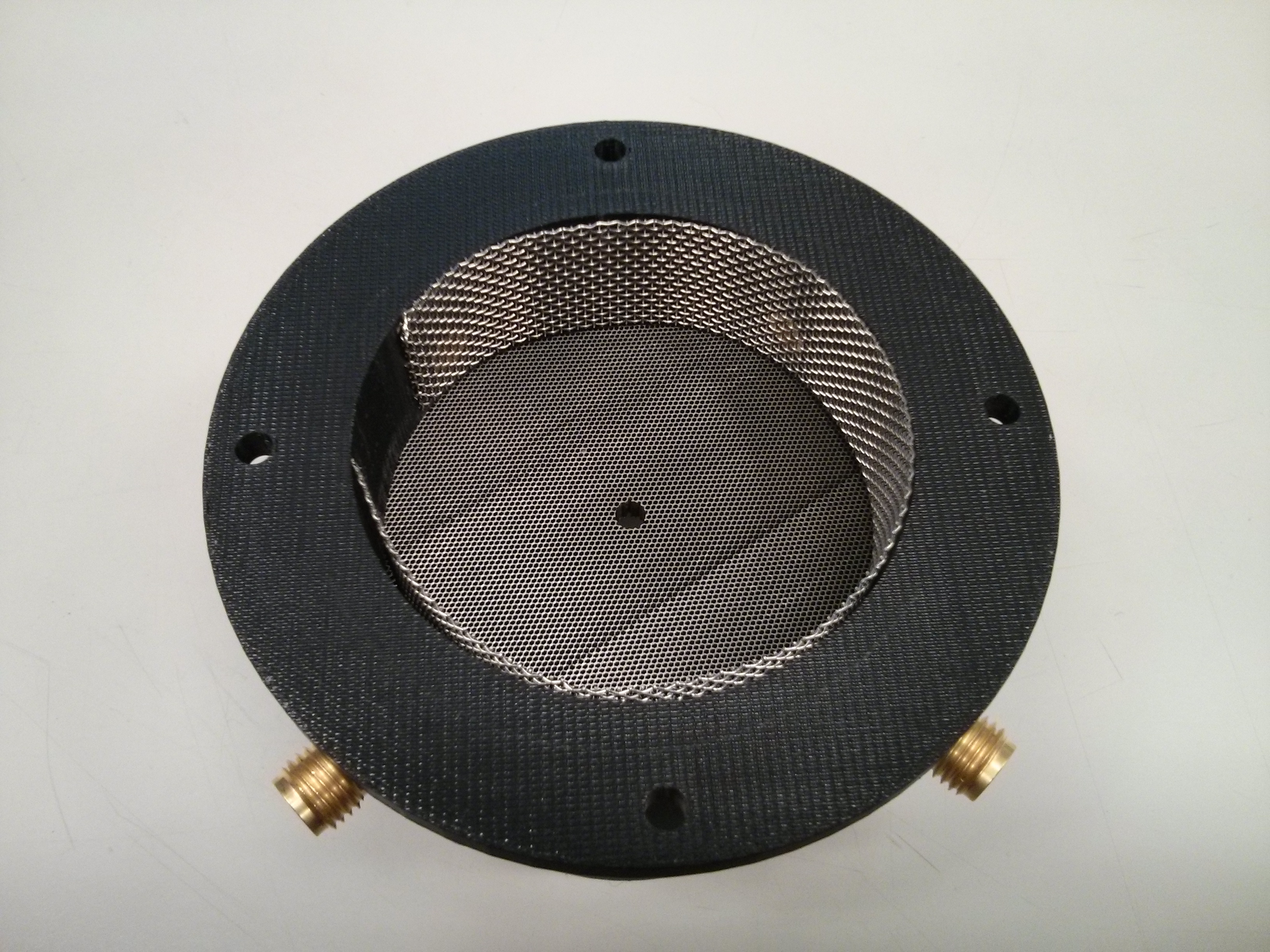

Coflow housing:

Fig. 1: Coflow housing, as provided.

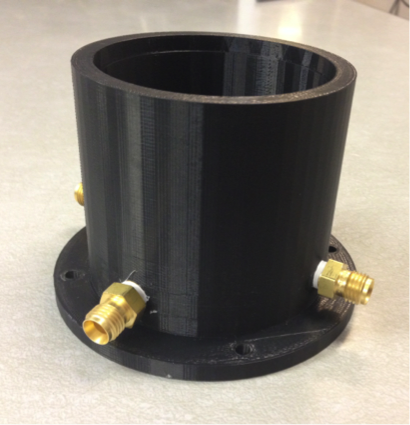

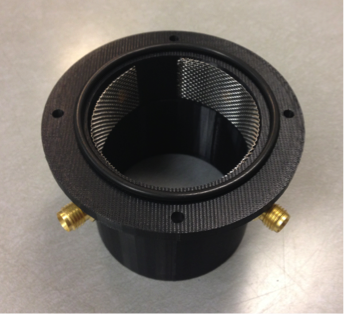

Fig. 2: Coflow housing with fittings inserted.

After inserting all four fittings, the burner should look like Fig. 2.

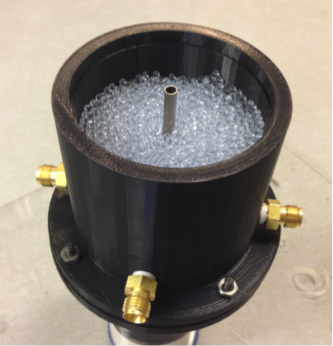

Fig. 3: Coflow housing with mesh and bottom honeycomb.

Bottom

Plate:

The

hole

in the center of the bottom plate is pre-drilled to 0.12.”

This allows for the option to press fit the fuel tube

through the hole. For this assembly guide, we will instead

use a bored-through 1/8” NPT fitting to connect the fuel

tube. This fitting is provided in the kit, as shown in

Figure 4.

FIg. 4: Bored-through NPT fitting.

Drill

the center hole to 11/32” and tap it. Then screw the fitting

into the hole, as shown in Figure 5.

Fig. 5: Bottom plate with NPT fitting inserted.

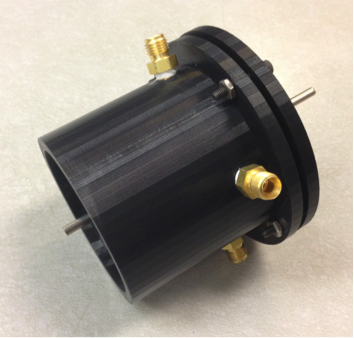

Final Assembly:

Place the provided o-ring over the bottom of the coflow housing as shown in Fig. 6. Note: the model shown does not have an o-ring grove, which will be part of the actual burner.

Fig. 6: O-ring placed over coflow housing.

Sandwich the o-ring between the bottom plate and the coflow housing. Use nuts and bolts to secure the two pieces together, as shown in Fig. 7.

Fig. 7: Coflow housing and bottom plate assembled.

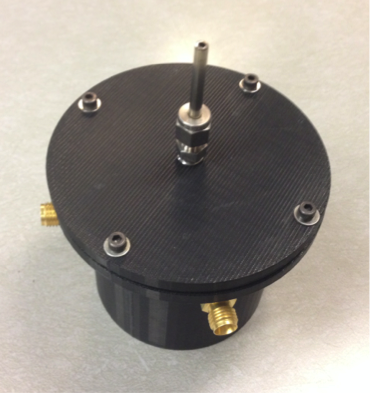

Insert the fuel line through the bored-through NPT fitting.

Fig. 8: Fuel tube inserted through bottom plate.

Fig. 9: Fuel tube made flush with burner top.